BD Rowa™ Dose

Personalized pouch packaging

- High speed and safety thanks to innovative technology and optimal transport routes

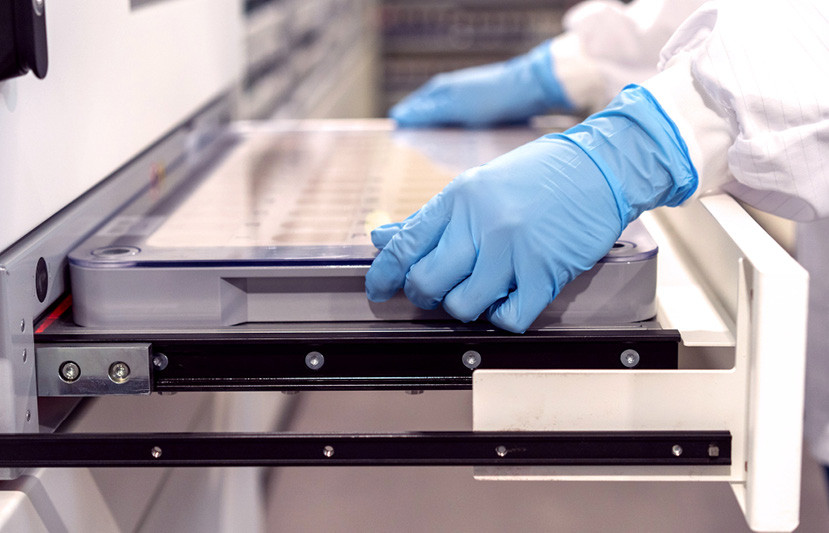

- Continuous pouch packaging process and direct access to all canisters, even during production

- Convenient and complete cleaning since all components can be dismantled.